When it comes to ensuring longevity and health of pipelines, the importance of internal examinations is paramount. Regular inspection of the interior of the pipeline allows us to find out different early signs of damage including denting, corrosion, cracks, and more.

With the advent of modern cameras and profiling, laser pipe profiling technology has emerged as a quicker, less physical, and more accurate pipeline inspection methodology. This is the technology of using lasers along with cameras for accurate identification of pipe joints, cracks, and deflection.

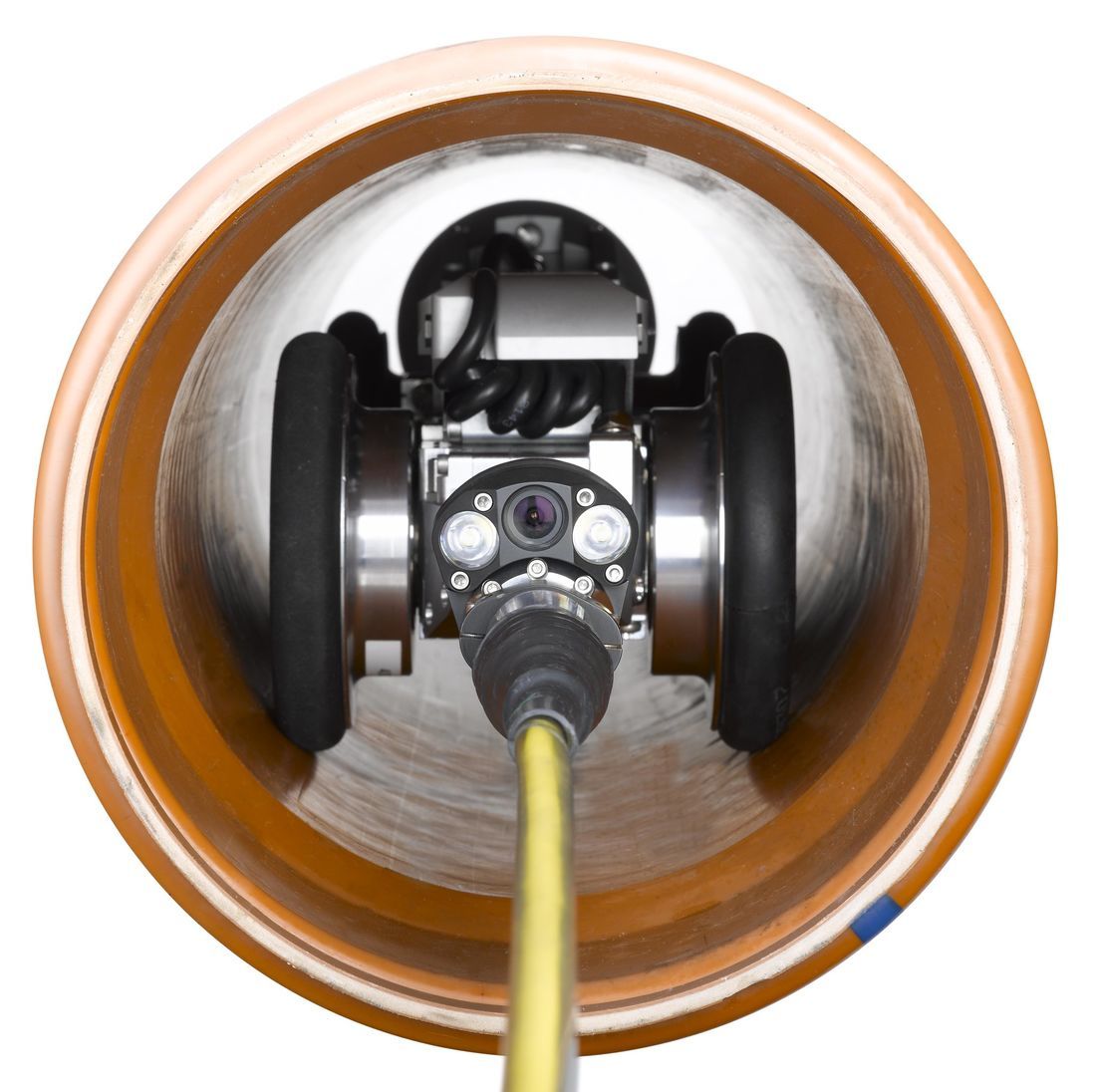

CCTV and laser profiling technology is one of the most trusted methods for pipe interior assessment.

Product Description

Jet Stream's Laser Profiling system provides computer generated pipe profile data. The laser profiler assesses the condition of a pipe by measuring the internal diameter, ovality (roundness) and capacity of a length of pipeline. Laser profiling equipment is attached to existing CCTV cameras. In situ footage is captured by the cameras and then computer analysed to produce the end user condition reports.

The Process

- A ring of laser light is projected onto the internal pipe surface.

- Laser image is captured by CCTV whilst camera moves through the pipe.

- Analysis is performed on the ring of light using specialised software to build a digital pipe profile.

Typical Applications

- Determining the internal cross-sectional area of a pipe

- Analysing capacity loss due to deformation

- Analysing capacity loss due to corrosion

- Quality assurance of new applications

- Post-rehabilitation pipeline assessment

- Quantifying defects, holes, and other

imperfections on existing and new assets - Measuring pipe diameter.